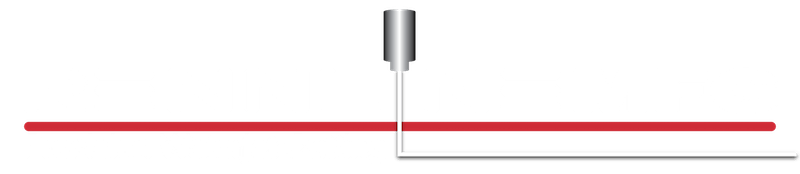

Here are some of the benefits to using a waterjet:

- Cheaper than other processes.

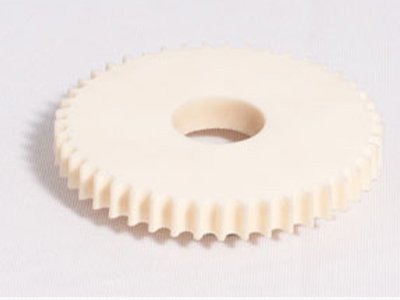

- Cut virtually any material: From Glass and Ceramics to Inconel and Titanium.

- Cut thin stuff, or thick material

- Make all sorts of shapes with one tool.

- Cuts a wide range of thickness up to 5.875″ thick

- No heat generated / No heat affected zones

- No mechanical stressesCut virtually any shape

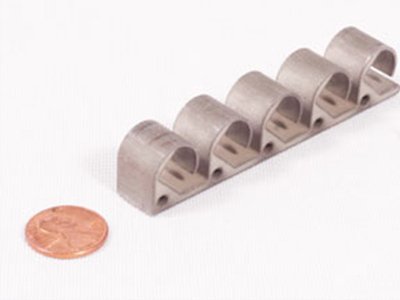

- Leaves a satin smooth finish, thus reducing secondary operations

- Clean cutting process without gasses or oils

- Narrow kerf removes only a small amount of material

- Abrasive jets are more enviornmentally friendly

- You can trade off tolerance vs. speed from feature to feature on your part.

- No “scaley” edges, which makes it easier to make high quality welds

- Machine Composite materials, or materials where dissimilar materials are glued together

- Machine Stacks of thin parts all at once.

When Comparing with Lasers

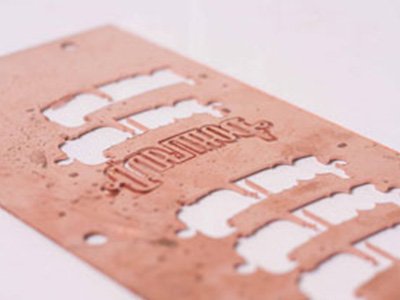

- Abrasive waterjets can machine many materials that lasers cannont. (Reflective materials in particular, such as Aluminum and Copper.

- Uniformly of material is not very important to an Abrasivejet.

- Abrasive Jets do not heat your part. This there is no thermal distortion or hardening of the material.

- Precision abrasive jet machines can obtain about the same or higher tolerances than lasers. (especially as thickness increases)

- Abrasive jets can machine thicker materials.

- Abrasive jets do not loose much “focus” when cutting over uneven surfaces.

When Comparing with EDM

- Abrasive jets are much faster than EDM.

- Abrasive jets machine a wider variety of materials. (virtually any material)

- Uniformity of material is not very important to an Abrasive jet.

- Abrasive jets can machine thicker materials.

- Abrasive jets are capable of the same tolerances on thin parts, and better on parts thicker than .5″

- No heat affected zone with abrasive jets.

- Can make bigger parts.

When Comparing Plasma

- Abrasive jets provide a much nicer edge finish

- Abrasive jets don’t heat the part

- Abrasive jets can cut virtually any material

- Abrasive jets are more precise

When Comparing with Flame Cutting

- Abrasive jets provide much nicer edge finish

- Abrasive jets don’t the part

- Abrasive jets can cut virtually any material

- Abrasive jets are more precise

When Comparing with Milling

- Huge savings in material yield versus milling

- No special tooling required

- Machine virtually any material, including:

- Brittle materials

- Pre-hardened materials

- Otherwise difficult materials such as Titanium, Hastalloy, Inconel, SS 304, hardened tool steel…

When Comparing with a Punch Press

- Lower cost per piece for short runs

- Place holes closer to the materials edge

- Faster turn-around

- Minimal set-up

- Thick materials are fine

- Brittle materials are no problem

- Hard materials are easy