What are Waterjet Cutting Edge Qualities?

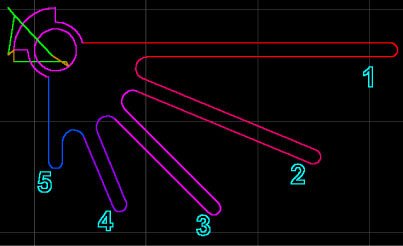

Cut edge qualities range from Q1 to Q5. Q1 is the fastest cut and is used primarily for material separation. Depending on the edge finish requirements, slower cutting speeds of Q2 through Q5 are selected. Parts requiring close tolerance geometry will of course require smoother edge finishes in that area of the part. (Note: Some other terms also used in the industry to indicate cut speed or edge quality – 100%, 80%, 60%, 40% & 20% or Fastest, Medium Fast, Normal, Better & Best.)

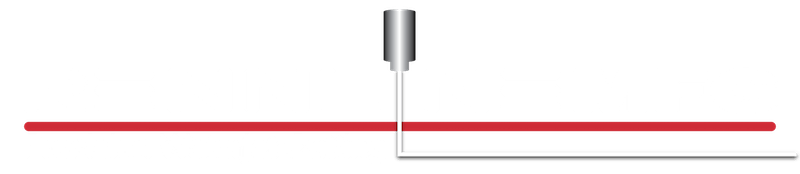

Cut Quality: Q1 (100%)

Description: Separation Cut

Requires Force to Separate

Cut Quality: Q2 (80%)

Description: Through Cut

Severe Bottom Striations

Cut Quality: Q3 (60%)

Description: Clean Cut

Moderate Bottom Striations

Cut Quality: Q4 (40%)

Description: Good Edge Finish

Limited Striation

Cut Quality: Q5 (20%)

Description: Excelled Edge

Light Striations, Minimal Edge Taper

Why is choosing the right edge quality important?

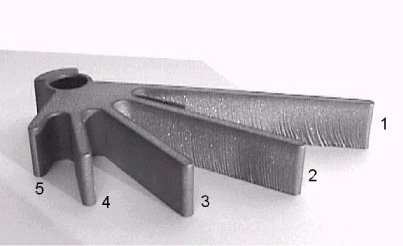

Depending on what the cut pieces will be used for, y our cuts may require different edge qualities. The edge quality directly affects the cost of the job, because it requires more or less time depending on the edge quality chosen. Your could ask two different companies for quotes to cut the same piece, out of the same material, and get two vastly different quotes because of the edge qualities. When getting quotes on waterjet cutting, always ask what edge quality you were quoted at. Requesting a small sample part, similar to the one shown below, will help determine your requirements and also be an example of what you can expect on your parts.